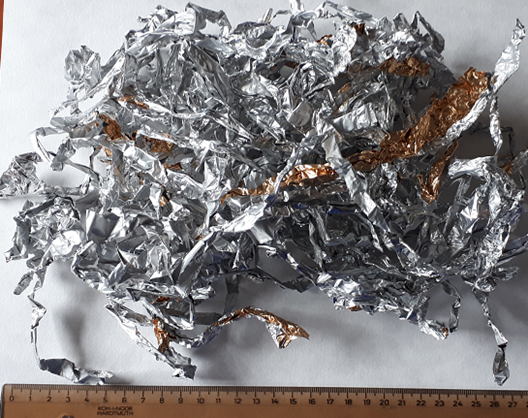

Waste aluminium foil is the residues or off-cuts of aluminium foil that are produced as a by-product of the production, processing or use of aluminium. Most often such waste is generated in industrial production. In order to minimize this waste, or at least to create a secondary raw material that could be returned to production and could be reused in the framework of circular economy approaches, scientists from the VSB-TUO CEET ENET Centre have embarked on a project entitled: Recycling of waste aluminium foil as a low-carbon substitute for input raw material, which involves AL INVEST Břidličná, a.s.

The great thing about aluminium is that it is a 100 % recyclable material. Therefore, the project wants to develop a technological process and technical documentation that outlines how to collect, process and reuse these waste aluminium foils in different industries.

The aim of the project is to gain new knowledge necessary for the development and verification of a new technological process for recycling of waste aluminium foil through industrial research and experimental development.

The key milestones in the project are:

- Return of waste coloured film to production

- Return of waste laminated film to production

- Creating a product with a recycled film content to reduce the cost of the raw material

The project will be implemented in two stages and divided into sub-activities, which will include in particular the mapping of available technological procedures and recycling technologies usable for refined aluminium foils, laboratory and semi-operational testing of selected procedures, technologies, experimental verification of the quality of recyclate produced by the developed technological procedure in the production of aluminium foils.

The successful outcome will be the replacement of primary aluminium with recycled aluminium. The moment this happens, the carbon footprint will be substantially reduced and new markets will be gained, or the needs of customers who, in addition to the usual quality, price or delivery times, require the use of recycled raw materials will be better met for our co-participating partner in the project, AL INVEST Břidličná, a.s.