Electrochemical Measuring Unit (EMU): Advanced Research Capabilities

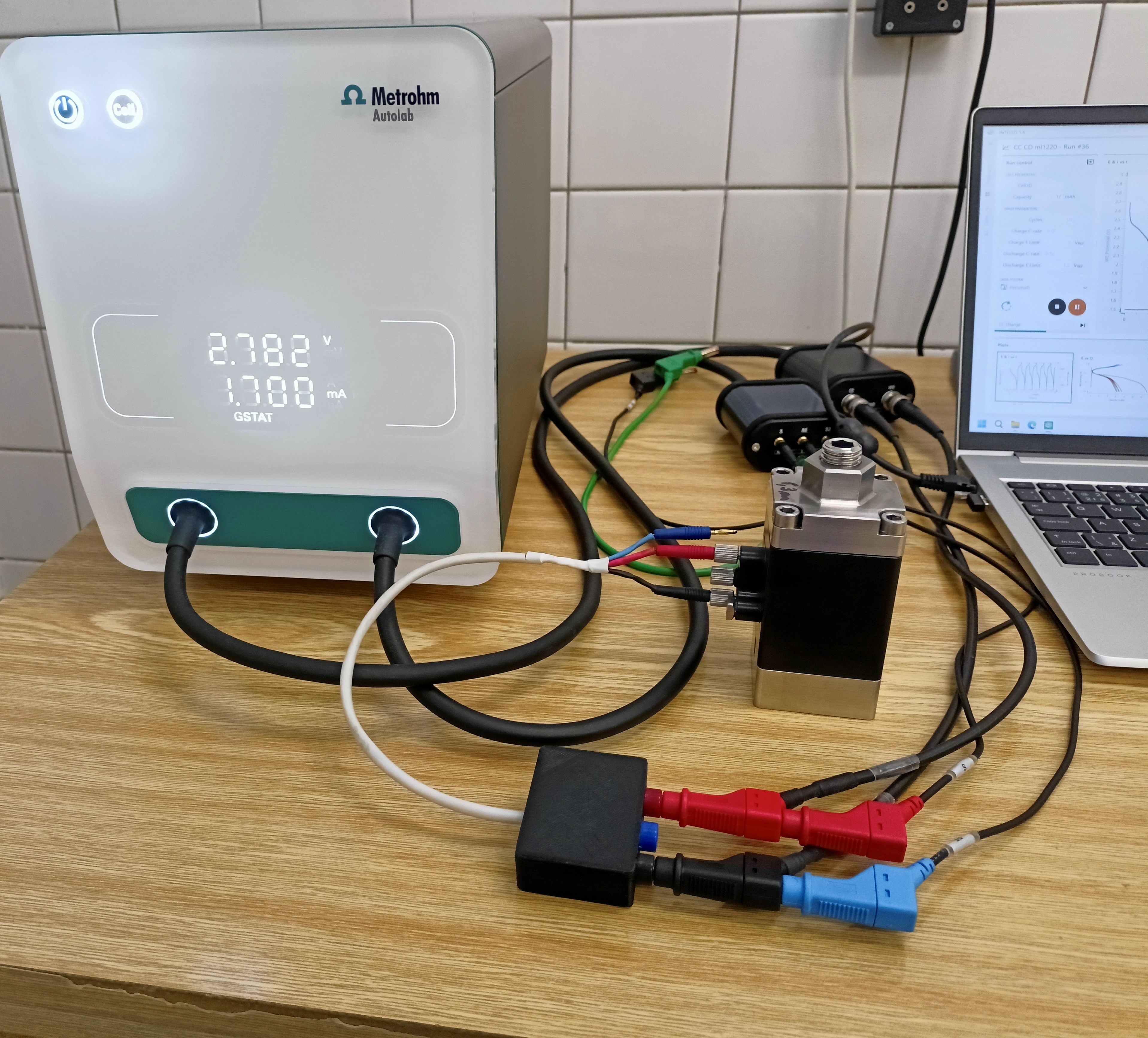

The EMU is designed for detailed measurement of battery and supercapacitor properties, as well as characterization of materials used in their production. Thanks to its advanced features, it allows the study of electrochemical processes in energy devices while simultaneously monitoring critical parameters such as pressure and temperature during operation.

Unique Features and Benefits

EMU boasts a number of innovative features that make it one-of-a-kind on the market:

- Compact design for easy handling and space-saving in laboratories

- Modular construction allows customization based on individual customer requirements

- Replaceable cartridges reduce measurement errors, save time, and lower operating costs

- Extensive characterization capabilities thanks to a wide range of electrochemical techniques

- Three-electrode support (two measuring, one reference) for precise analysis

- The measuring cell can be equipped with additional features tailored to research needs, such as:

- Pressure sensor for monitoring volume changes of the sample

- Temperature sensor for monitoring thermal changes

- Heating element for controlled temperature changes during experiments

Wide Range of Applications

EMU is applicable not only in the development of new materials for battery and supercapacitor construction but also in other research fields. It is made from chemically and mechanically resistant materials, ensuring long service life and durability in demanding laboratory environments.

EMU will greatly simplify, accelerate, and reduce the cost of electrochemical parameter measurements in research institutions, such as universities, academies of sciences, research centers, and companies in the energy industry.

Teamwork and Scientific Excellence

The development of EMU is the result of a multidisciplinary team of experts from FMST and CNT CEET, led by Vlastimil Matějka (FMST) and Grażyna Simha Martynková (CNT). The design and construction of EMU was spearheaded by Oto Mušálek (CNT, FMST), with support from doctoral researchers Lukáš Plesník (CNT) and Ondřej Mušálek (FMST), who joined during the two-year development of the measuring cell. To improve software communication, Vratislav Mareš (FMST) was also brought on board.

Patent Protection and Future Perspectives

The EMU’s groundbreaking design is currently undergoing patent registration, confirming its unique character and exceptional scientific and technological contribution.

The development of EMU stands as a model example of successful interdisciplinary collaboration between FMST and CNT CEET. The synergy of expertise in materials engineering, electrochemistry, and nanotechnology enabled the creation of a device that opens new frontiers for research in energy materials.

EMU not only strengthens the position of FMST and CNT as leading research institutions in materials science in the Czech Republic, but also opens new pathways for scientific discovery in the field of chemical energy storage. The interdisciplinary approach used in the development of EMU lays a solid foundation for further groundbreaking innovations in this strategically important sector.

By developing a multifunctional device for testing sustainable materials for batteries and capacitors, the project has also achieved synergy with the MATUR project, jointly implemented by both FMST and CNT.