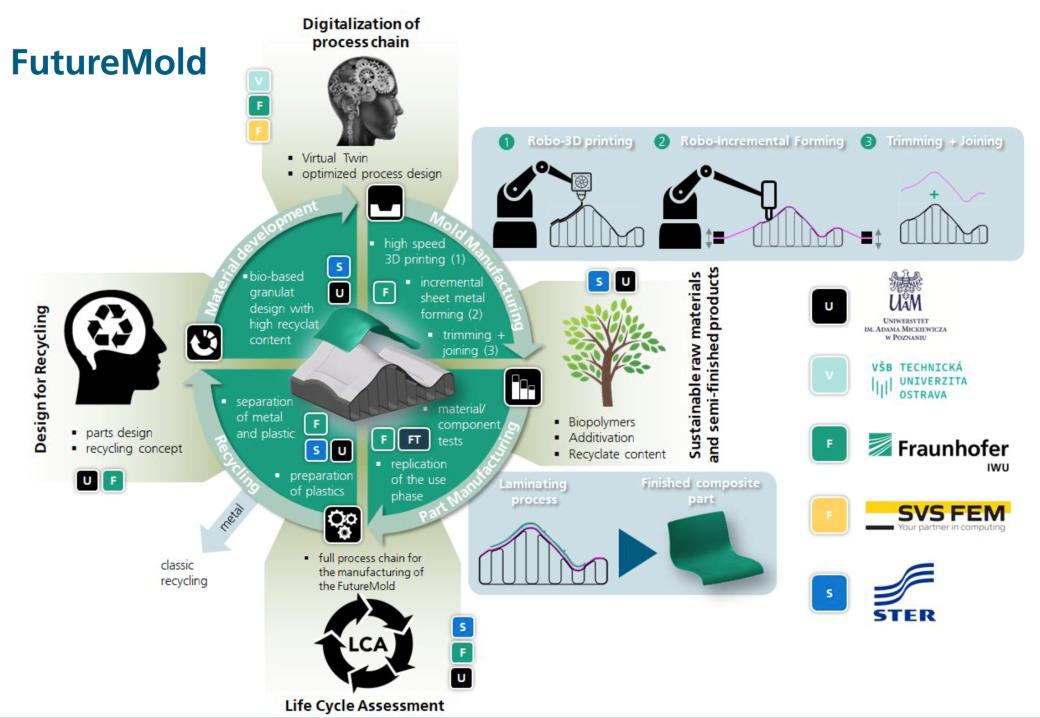

The main objective of the FutureMold project is to develop a novel, cost- and material-efficient hybrid method for manufacturing molds for lightweight fibre-reinforced plastic (FRP) components by combining 3D printing and incremental sheet metal forming (ISF). The base body of the mold is produced by 3D printing a biopolymer, onto which a metal layer is subsequently robotically applied using the ISF method. This hybrid manufacturing process combines rapid additive manufacturing with flexible sheet forming, which minimises material consumption, shortens production time, and simultaneously increases the service life of the molds. A key element of the approach is a detachable joint between the polymer core and the metal layer, which facilitates recycling and secondary material use.

One of the project's goals is to significantly accelerate numerical ISF simulations, which are essential for the correct design of tool paths and the prediction of final shapes.

"Current incremental sheet metal forming processes face significant challenges, including lengthy simulations that can take several days to complete. The goal of this project is to dramatically reduce these times while maintaining high accuracy," said Tomáš Brzobohatý from the IT4Innovations National Supercomputing Center, the principal investigator at VSB – Technical University of Ostrava.

Traditional FEM (Finite Element Method) simulations provide high accuracy but are computationally demanding, often requiring days or even weeks of calculations. The project therefore integrates High-Performance Computing (HPC), FEM simulations, and machine learning techniques to replace or complement FEM simulations. The developed models, based on machine learning and advanced neural networks, can predict ISF processes within minutes, thereby enabling rapid optimisation of the forming strategy.

The project results promise significant socio-economic impacts, including reducing production costs and carbon dioxide emissions by up to 20 per cent, particularly in engineering sectors using lightweight fibre-reinforced plastic (FRP) components, such as the railway, marine, and aerospace industries. Additional benefits are expected in the creation of new market opportunities and the promotion of sustainable manufacturing methods. The project, which will run until 2026, is part of the international EU-funded initiative M-ERA.NET.

Text: Martina Šaradínová, PR Specialist for R&D

Photo: AI-generated illustrative images & project archive

Project FutureMold was selected in the Joint Transnational Call 2023 of M-ERA.NET 3, which is an EU-funded network of about 49 funding organisations (Horizon 2020 grant agreement No 958174). The project is funded by the Saxon State Parliament, Saxony, Germany, the TACR, Moravian-Silesian, Czech Republic and the National Centre for Research and Development NCBR, Poland.